Consumers are increasingly looking for beauty solutions that meet their specific skin needs as well as ethical concerns. Millennial and Gen Z consumers, in particular, see beauty as a way to express their individual identities.

As such, they are eschewing the one-size-fits-all notion and are now looking for products that are tailored to their own needs and concerns.

In recent years, cosmetic brands have been answering the call with products that have a varying degree of personalisation from start-ups like Proven to international names like Clinique.

“Increasingly, end-consumers want a fuss-free yet highly bespoke shopping experience that promises them an intelligent and adaptive formulation for their skin care and personal care. We see early movers in this market – for example Function of Beauty – attracting investor and consumer interest,” said Chin Wooi Cheang, executive director of global manufacturing operations, Meiyume.

This trend is coinciding with the acceleration of digital commerce, which was triggered by the COVID-19 pandemic.

“This comes especially at a critical time where e-commerce sales have been skyrocketing and many of our new customers are purely at online play without a brick-and-mortar presence.”

These changes are challenging third-party manufacturers like Meiyume to rethink their manufacturing supply chain.

For instance, the company is now seeing the need to have “deep integration” between its manufacturing systems and the brand’s ordering and fulfilment systems, said Cheang.

The growth of personalisation is also pushing the company to accelerate its formulation expertise so they can offer exciting and effective products for specific consumer needs and concerns.

A new bespoke system

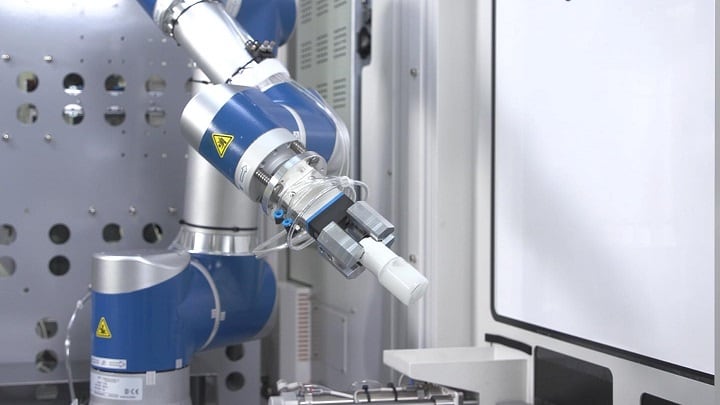

In July, the company announced that it had developed a manufacturing system to cater to the increasing demand for personalisation.

The system delivers small batches of made-to-order formulations that can be tailored based on the preferred active ingredients, fragrance, and colour.

“This manufacturing system is a proactive investment on Meiyume’s side in response to the increased demand we see in the marketplace for bespoke products,” said Cheang.

According to the firm, it has 60 ready-to-go formulas and packaging with turnaround times of around five to seven days from order placement to delivery.

Customers can also customise its own formulations with choice of actives and fragrances, which can then be paired with the firm’s own packaging solutions.

“We can add in different elements that resonate with your brand identity and packaging finishes to give your products a bespoke touch. What you get is an end product that is perceived as more sophisticated and valuable, creating greater customer stickiness,” said Cheang.

The system is now able to develop liquid personal care products such as shampoo and the company is studying how it can adapt this for higher viscosity products, like creams.

“There are endless ways to improve on the machine and we are firm believers of rapid prototyping and innovation. We wish to work with an anchor customer to identify the right ‘next improvements’ for them. These could range from increasing formula count to working on more diverse range of products,” said Cheang.