The method produced extracts that better controlled melanin production and helped skin cells close scratches faster.

The peer-reviewed study was conducted by BeNatureBioLab and Kangwon National University.

According to the authors, hot-melt extrusion (HME) is a continuous, solvent-free process already common in the pharmaceutical industry that can help brands develop cleaner, more efficient brightening and regeneration actives from botanical sources.

Why this matters for industry

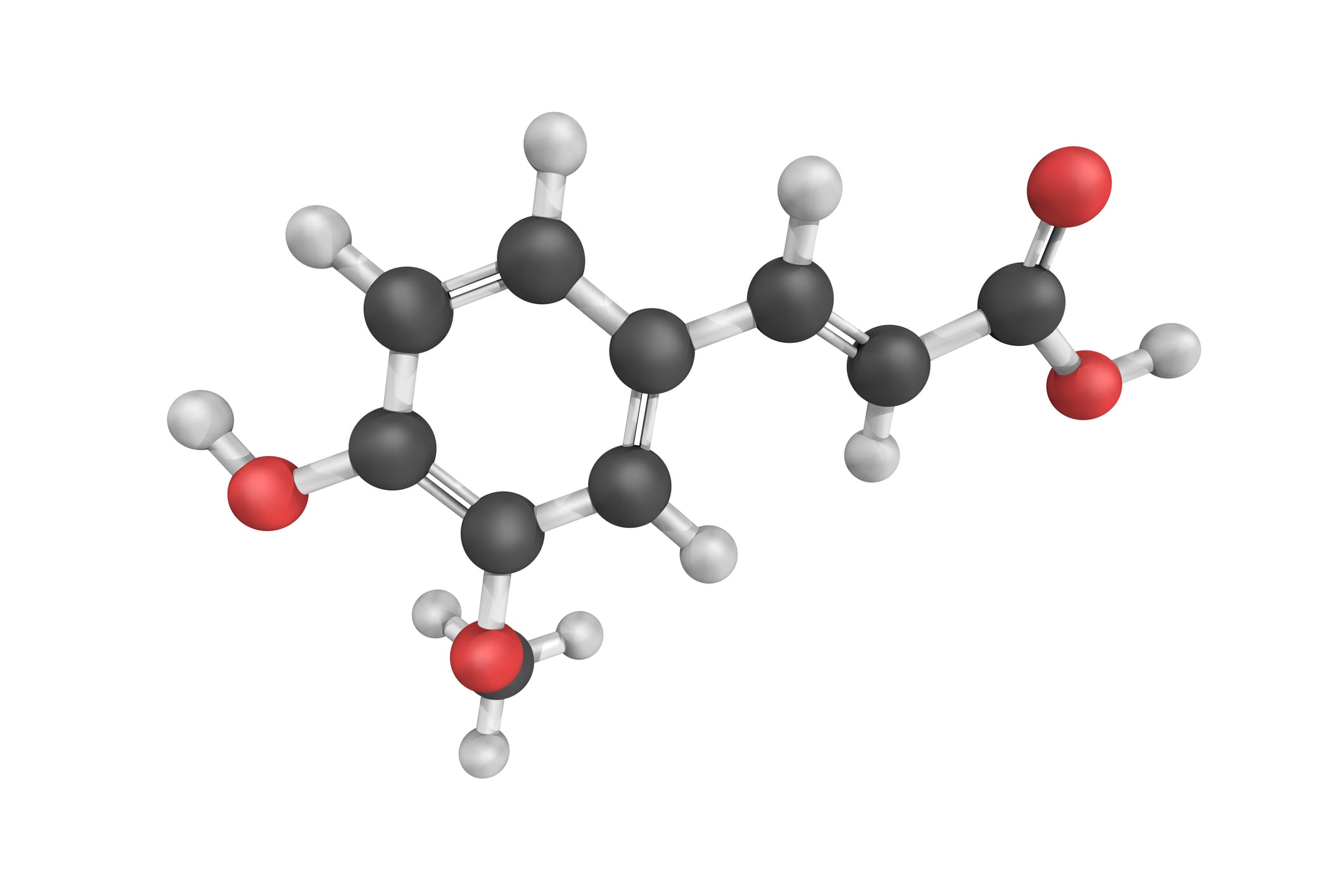

Ferulic acid is a popular antioxidant used in skin care to protect against UV damage, reduce inflammation, and even skin tone. It often pairs with vitamins C and E for stronger photoprotection.

The problem is that it is hard to extract at high strength without solvents, which drives up costs, reduces consistency, and raises sustainability concerns.

By using HME, the researchers extracted more ferulic acid from plant powders and changed the particles so they dispersed better in water.

In lab models, these changes produced stronger effects on melanin control and keratinocyte migration, two key levers for brighter and more even skin. As the process is continuous and solvent-free, it also supports the sustainability claims that brands want to make.

Actions and results

The researchers applied HME to powdered CO and AG, breaking down cell walls, freeing bound actives, and creating smaller, more uniform particles without organic solvents.

They blended the herbs with small amounts of lecithin and ascorbyl palmitate to improve dispersion and protect against oxidation, plus extra ferulic acid to prime antioxidant effects. After extrusion, the powders were freeze-dried, milled, and extracted in warm water.

Subsequently, the researchers reported that in CO, content jumped 22.7-fold, from 330 to 7,480µg/g. In AG, it rose 4.4-fold, from 529 to 2,339 µg/g. For formulators, this means much more actives per gramme of extract, supporting either lower use levels or stronger claims.

Particles also became smaller and smoother in HME powders as compared to raw powders, which had rough, porous surfaces. This was significant, as smaller particles disperse better in water and are easier to use in serums or essences.

Furthermore, the study found that melanin production dropped further with the HME powders. In melanocytes, raw CO and AG reduced melanin to about 66% of control. While HME extracts cut this further, down to 40% to 45%. Arbutin, used as a control, brought it to 34%. While not stronger than arbutin, the HME extracts moved noticeably closer.

The researchers also noted improvements in keratinocyte migration. In scratch tests, HME-CO closed wounds to 96% after 48 hours, versus 89% for raw extract and 80% for control. HME-AG reached 98%, compared to 81% (raw) and 75% (control). This pointed to stronger skin repair potential.

Implications for brightening and repair claims

The results suggested that HME-processed CO and AG could deliver target brightening at lower doses compared to raw extracts. Ferulic acid was also found to have stabilised vitamin C, making these extracts attractive for C/E/ferulic serums.

While the extracts did not surpass the effects of arbutin, they advanced closer to that benchmark. For brands aiming for hydroquinone-free brightening with familiar antioxidant chemistry, this offers a credible path.

In terms of repair, scratch assay suggests HME extracts may support faster re-epithelialisation, or skin cell migration to close surface damage. This is important for post-inflammatory marks, irritation, or procedures, where faster recovery improves tone.

While scratch tests are a basic lab model, the improvement here was large enough to justify further in vivo studies.

Formulation and scale-up

HME is a continuous process, offering more consistency than batch extraction and fitting into existing production lines. With limited solvent use, it supports greener manufacturing and simplifies compliance.

As the extracts were water-extracted after HME, they would be best suited to water-based formats like toners, essences and ampoules. Smaller particles already improve dispersibility, though co-solvents or solubilisers can be added if needed.

Additionally, the researchers found that ferulic acid paired well with vitamins C and E, and noted that brands should watch pH, colour drift, and oxygen ingress. Airless, opaque packaging could also help.

As the study used lecithin and ascorbyl palmitate during processing, suppliers should disclose these and confirm regulatory status. Labelling could use names like “Cnidium officinale rhizome extract (hot-melt extruded)”, with clarification if ferulic acid is standardised or fortified.

Safety and limits

One of the study’s limits is that its evidence was solely in vitro, so brands should avoid making clinical claims until further studies can confirm these.

While safety margins in cells were generous, the Angelica species can contain furanocoumarins, which may be phototoxic. Processing may reduce this risk, but suppliers must test and confirm compliance.

HME can also alter sensory properties, so colour and odour should be evaluated early, especially in brightening serums where changes are noticeable.

Next steps

Ingredient makers could move toward GMP-grade, HME-standardised extracts with set specs for ferulic acid, particle size, and in-vitro benchmarks.

At the same time, future work could include mechanism studies on tyrosinase, MITF, and inflammation pathways, clinical tracking of L* values and fading of dark spots, and pairing extracts with vitamin C/E sunscreens or serums for photoprotection.

In addition, regulatory dossiers should cover composition, impurities, stability, and any furanocoumarin controls.

Takeaway for suppliers and brands

HME offers a clean, scalable way to boost botanical extracts. It concentrates ferulic acid and reshapes particles for stronger lab performance in brightening and repair models.

For suppliers, this is an opportunity to launch standardised HME extracts with strong specs and data. For brands, these materials can anchor “brighten and repair” concepts, especially in C/E/ferulic serums.

The researchers concluded: “Taken together, the findings underscore the utility of HME as a green, solvent-free processing technology capable of enhancing the physicochemical characteristics and biological efficacy of herbal materials.

“The results support the potential application of HME-processed CO and AG as active ingredients specifically designed to enhance skin brightening and accelerate skin regeneration, offering promising opportunities for next-generation functional cosmetics and therapeutic formulations.”

Source: Cosmetics

“Eco-Friendly Enhancement of Ferulic Acid-Rich Extracts from Cnidium officinale and Angelica gigas via Hot-Melt Extrusion for Skin Brightening and Regeneration”

https://doi.org/10.3390/cosmetics12050197

Authors: Yoo-Na Jeon, et al.