Everyone is talking about 3D printing, but to what extent - if any - is it currently being used in the packaging business?

I like to use the term additive manufacturing, which encompasses 3D printing as well as other additive techniques. Additive manufacturing has a significant amount of use in the packaging industry, but mostly as a tool for rapid prototyping. There is an example currently of it being used in commercial production of primary cosmetic packaging for Anita’s Balm, which uses a 3D printer and PLA plastic to create its containers.

What benefits does it bring to the packaging industry?

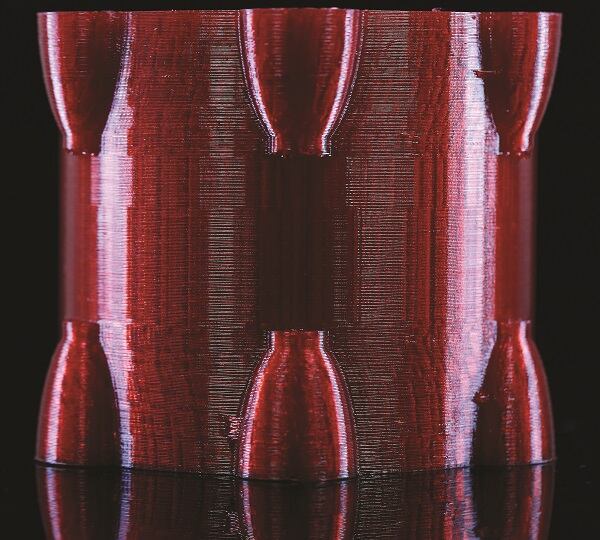

Additive manufacturing offers the tools to bring precision prototyping in-house, directly from the computer into an in-hand object, aiding in design verification, approvals and consumer testing. The additive nature of the fabrication itself also opens up new structural and design opportunities before unrealised.

How can 3D printing be used more effectively in this area?

With the widespread interest in additive manufacturing, there is a boom in processes, machines, and service models being offered, allowing for individuals and business of any size to get into the arena. A variety of companies offer printing services, allowing a business to reap the benefits of the technology without investing in equipment or employee training.

What challenges and potential pitfalls does the packaging industry face as it looks to incorporate 3D printing more effectively?

Additive manufacturing is a tool, and like every tool it is fantastic for certain situations and not applicable in others. Though very successful at some things (precision, customization, structural complexity), additive manufacturing is not currently suited for high volume commodity production. Using the technology to its best advantage will consist of finding the right challenges for it to solve, not simply incorporating a “trend”.

What will 3D printing mean for manufacturers in the future?

Efficiency and customization. Additive manufacturing has proved itself invaluable in reducing the steps in design development. It is also facilitating fabrication though improvements and tweaks on current manufacturing lines, creating custom bearings, gears and short run tooling.

Things are moving quickly - what sort of timescale would you put on a more widespread use of 3D printing in packaging?

When is additive manufacturing going to replace injection blow molding? It’s not. They are different tools for different needs. More than a ramp up in speed or technological improvements, though those continue to arrive, adoption will be a function of the increase in well-versed users.

Ultimately what will this all mean for the consumer?

Design freedom and one-off production can be an outlet for consumer involvement, provide customization, meet underserved needs, and serve a specific set of consumers or even an individual. Brands and manufacturers have an innovative new tool in their toolbox with which to add unique value for their customers.

Sarah Hoit will be presenting at Luxe Pack New York 2015, which runs May 13-14 in Manhattan. For more information about her talk and the program, please click here.