Promotional Features

K-beauty inspiration: how to formulate multi-balm stick

K-beauty has changed the beauty industry in the past decade with its amazing innovations. A multi-use product bringing both hygiene and convenience to a busy modern life is becoming increasingly attractive to Korean consumers.

Beauty sticks made for multi-purpose use by combining the functions of cream, serum, makeup and even facial mask have quickly become one of the biggest K-beauty trends this year. However, formulating stick products is more challenging than creams and serums. The key attributes that are previously linked to lipsticks, such as stability, firmness and pay-off, now need to be re-evaluated for whole facial applications.

The oil components within a stick formulation function as a solvent for the waxes and a carrier for the pigments. “Stick sweating”, the phenomenon which is very familiar to makeup formulators, is usually caused by poor wax solvency which creates a coarse, non-homogenous structure, leading to fine oil droplets on the surface of the stick during small temperature fluctuations or product storage. In very unstable systems, variations such as temperature fluctuation, which is very common in tropical regions, or improper storage, can lead to the stick melting completely.

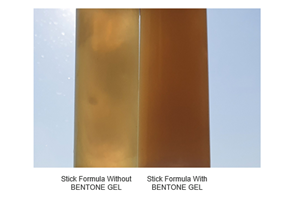

Hectorite based organoclay gels of the BENTONE GEL® series can create a network in the stick’s oil phase, working together with the waxes in the system to promote a fine, homogenous crystalline structure that leads to an increased stick integrity. Unlike the crystalline mechanism of waxes, the gel network is built up via hydrogen bonding formed by the hydroxyl groups on the edges of the organoclay platelet. This network is much more thermo-resilient than the one from waxes, thus the BENTONE GEL® can help to stop the stick system from melting at high temperatures. The stability test shows that the Moisture Boost Serum Stick (F-1012-01) with 10% BENTONE GEL® LC V (INCI: C9-12 Alkane (and) Disteardimonium Hectorite (and) Triethyl Citrate) did not melt when stored at 40°C, while the benchmark formula without BENTONE GEL® partially melted. The prototypes have also been stored in the oven at 50°C, and the result shows that the one without BENTONE GEL® partially melted in an uneven way.

Picture 1: Moisture Boost Serum Stick (F-1012-01) with and without 10% BENTONE GEL® LC V stored at 50°C

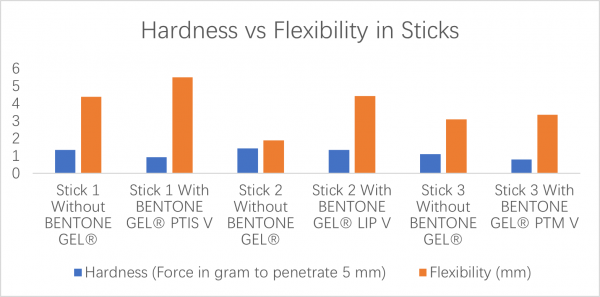

Another important aspect of stick application is the firmness. It describes the interaction between the oils and waxes within the formulation and can be controlled by altering the oils or waxes used. Within a formulation, formulators need to carefully select the paste-like materials that can be used to create micro-crystalline or gel-like structures to ensure more elasticity and are less prone to potential breakage. On the other hand, if the stick texture is too hard, it will impact another key attribute – the pay-off. Pay-off is a measure of the amount of product deposited on the skin when applying, and is directly related to the formulation’s wax structure. Pay-off is important to ensure even and thorough covering of area with product, and can be inversely proportional to firmness i.e. the softer formulations provide increased payoff and vice versa. This relationship creates a challenge for formulators – balancing the need for a firm formulation while maintaining a good pay-off, the two fundamental attributes where good performance is expected by the customer.

Hectorite based organoclay gels make the stick structure more elastic, and the hydrogen bonding network structure will be fully formed when the product is in the container. When shear is applied, the platelets align flat on the skin, giving a beautiful application. Generally, BENTONE GEL® will make a stick softer, so that a better pay-off on application can be achieved. At the same time, it will give a stick more flexibility, so that it is less prone to breakage.

Picture 2: Hardness vs. flexibility in stick formulas with various BENTONE GEL®s

Current beauty sticks have gone beyond skin moisturization only, and more diversified multi-purpose sticks are emerging in the market, such as clay mask stick, sun care stick, highlighter stick, foundation stick and many more. The variety of applications brings more insoluble ingredients like sunscreens, particles, pigments, clays and some actives into the stick, causing more challenges to the formula system.

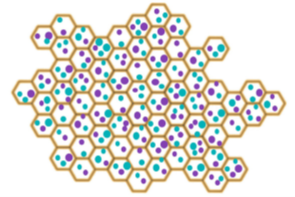

The BENTONE GEL® series offers a unique rheological performance in both single oil systems and the oil phase of an emulsion. The honeycomb like network formed by the gel, often referred to as a house of cards, can help the oil droplets, pigments and other particles to be evenly suspended and stabilized in the system in a much finer texture. The extraordinary suspension performance of BENTONE GEL® leads to a much more uniform and stable stick and ensures replication of the formula performance from batch to batch.

Picture 3: Idealized two-dimensional representation of the network formed by a BENTONE GEL® for stabilizing actives and particles

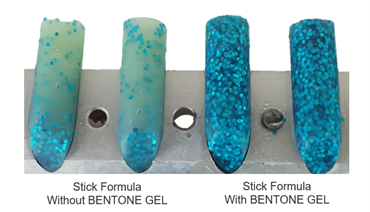

Particularly during the molding process in production, when oils and waxes are still liquid, sedimentation of the particles is of concern. Picture 4 depicts glitter in a stick base, that was put into the mold at 80°C, and without organoclay gel (10% BENTONE GEL® GTCC V), all the glitter sedimented. It is clearly shown that the incorporation of BENTONE GEL® into the stick system will help improve the suspension performance at large.

Picture 4: BENTONE GEL® helps to improve the particle suspension in a stick formula

One extra benefit brought by is the smooth and velvet sensory. Most stick formulas are wax-based, which often leave a greasy feeling when applied to the whole face instead of lips only. Hectorite clay is treated with quaternary ammonium compounds, which cover the hydrophilic surface structure of the clay with organophilic (hydrophobic) material to facilitate the clay to build the network in the oil phase of a system. These so called organoclays demonstrate enhanced skin-feel by masking greasy or tacky components and impart a pleasant residual silkiness to the skin.

What is hectorite?

Hectorite clay, named after the originating area in a location near Hector, California, is an exceptionally pure, non-toxic, non-bioaccumulating, three-layer clay of the smectite family. It is sourced from the world’s purest hectorite mine, near Newberry Springs, California. The hectorite clay was created from volcanic ash by hydrothermal means. The salt beds found in this area in combination with hot springs yielded a unique clay mineral structure that is different to other smectite clays. The extremely efficient swelling capability and network stability of hectorite is due to the uniform charge density distribution, as the clay was built from a quick volcanic eruption; while Bentonite is built from a longer-lasting weathering process with less uniform charge density distribution. The hectorite clay ore is selectively mined using open-pit mining operations, and the wet processing removes impurities to create different grades of hectorite clay. The platelets are remarkably uniform with respect to elemental composition, charge density distribution and charge location. The hydrothermal conditions create platelets with a thin shape, which results in a favorable edge-to-face surface ratio.

BENTONE GEL® products bring multiple benefits to the oil phase of a formulation while remaining up to 99% naturally derived according to the ISO 16128 standard.